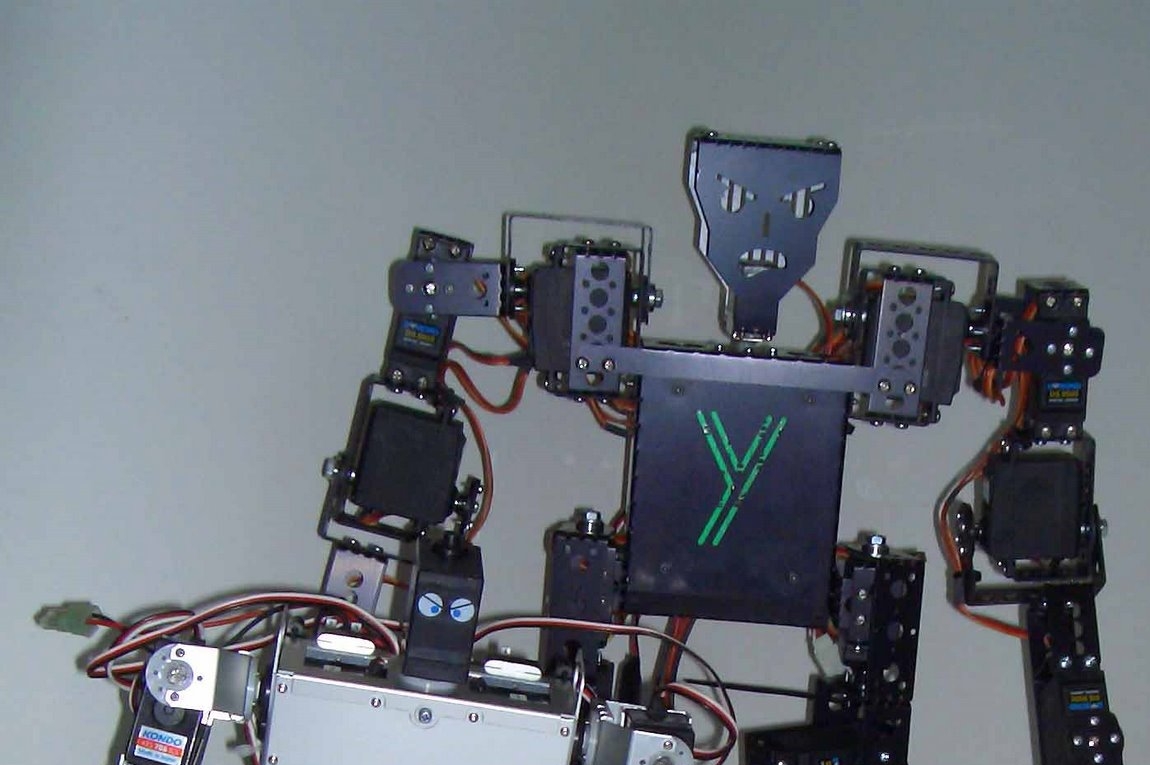

YDNA1 humanoid robot project

Project summary:

YDNA-1 (Why DNA) is a biped and uses custom built brackets by noDNA. To save cost it uses Dymond DS9500 digital servos, no intelligence, just a Lynxmotion SSC-32 servo controller.

Project was realized in September to November 2006, most of time was consumed by the bracket design and CNC milling on our small machine which took about 20 minutes per part. I did build 3 pototypes actually, here is the final 3rd prototype. All parts have been anodized in black to make him look cool…

Chest design and brain:

The chest houses the Lynmotion SSC-32 servo controller and/or Atom Bot board. The robot is driven by a 6V NiMH battery pack.

Servos:

I used the low cost (30 EUR/unit) but relatively strong Dymond DS9500 servos (12kg/cm) from Stauffenbiel. They have metal gear and a plastic servo horn attached. After having assembled the robot and done some tests I found the Dymond servos do not provide enough power to the robots joints to lift himself up from the floor after falling. So I started to replace some of the critical joints by Hitec digital servos HS-5995TG (can be seen here on hip and upper leg, heat sink is a good nd nice feature)

Servo brackets:

All servo brackets have been designed on noDNAs CNC mill. We used 1mm aluminium and carefully designed all brackets to fit exactly to the Dymond servos and to provide ball bearings on all brackets. The bracket design uses a lot of weight saving holes without sacrificing stability. Brackets have been bent on a small custom bent table and anodized to harden them and make them look cool.

Head:

The head is currently a pan head only and will be a camera head with pan/tilt. It uses the HS-422servo. The current head design is just for fun…

Technical data:

Weight: 1.6kg

Size: 45 cm

Servos: 21 (20 DS9500, 1 HS422) (finally replaced 6 * DS9500 by 6*HS-5995TG)

DOF: 6 Leg, 4 Arm, 1 Head

Here you see a size comparison of YDNA1 with Kondo KHR-1:

He has good force and can carry a bit of payload. Of course he can stand on one leg and knee down on one leg. Can hop a bit, did not want to stress this because servos are expensive… Too bad I had to give up this project in the end because I moved to a new location and now have only a small room for manufacturing singular parts for repair and prototyping. Might change again in the future. Enjoy!